Cost-Effective Turbocor Chiller Retrofits with Centrifugal Compressors

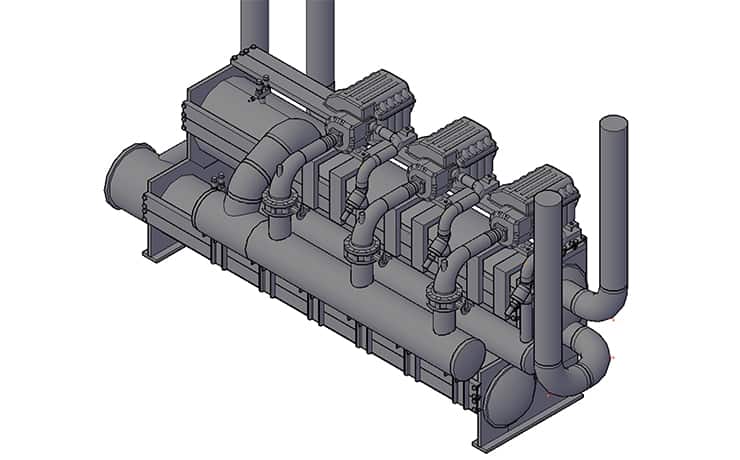

Can’t find money in the budget to replace your aging, high-maintenance, water-cooled chiller? Turn to Bullock, Logan & Associates for retrofitting that can effectively update your chiller to meet industry standards. With our retrofitting services, you won’t need to worry about your chiller breaking down and requiring a costly replacement unit. We can retrofit nearly any water-cooled chiller with a centrifugal oil free compressor that helps maximize the longevity of your chiller while helping you save money in the process.

Improve Your Chilling Systems with Turbocor Compressor Retrofits

Rather than spending the time and money on a replacement chiller, you’ll benefit from the efficiency of a simpler Turbocor compressor retrofit that gives your facility everything it needs for chilling and cooling. If you’re looking for a way to easily improve your chilling systems, our oil-free retrofits can make the process simple and painless.

Benefits of Turbocor Compressor & Chiller Retrofitting

There are many reasons why you should consider getting Turbocor chiller retrofitting from Bullock, Logan & Associates. While you may be tempted to replace a chiller, the cost of a replacement can far outweigh the benefits, but retrofitting your Turbocor compressors can enhance them in many ways. A reliable oil free chiller system can become a valuable asset to your facility with our retrofitting services. You’ll be able to see many improvements that you might otherwise remain without as your system deteriorates due to wear and tear.

Benefits of retrofitting a chiller include:

- Much lower cost than replacing the existing chillers, simple payback less than 2 years

- No “disturbing” the existing mechanical room and existing piping

- Re-using the existing condenser and chiller barrels is sustainable and environmentally friendly

- Eliminate expensive helicopter lifts of new chillers

- Convert chiller to new environmentally friendly refrigerants (R134A)

- Update existing chiller parts with new controls and power panels

- Turbocor compressor retrofits dramatically reduce noise and vibration

- Energy efficiency – reduce energy consumption, increase operating efficiency by 25% to 50%

- Add 25 more years of life to the existing chiller

- Custom-engineered chiller retrofit by Bullock Logan & Associates

These benefits make retrofitting Turbocor chillers as effective as replacing the entire system with a new unit. You can experience optimum efficiency and productivity that you’ll begin to see turn into increased profitability. If you think you need a chiller retrofit today, we’re ready to help determine the extent of your project and get started immediately.

Turbocor Chiller Retrofit vs. Replacement

When your facility’s chiller system starts to show its age, you’re faced with a pivotal decision: retrofit or replace? Bullock, Logan & Associates provides solutions for both options, but understanding the advantages and disadvantages of Turbocor chiller retrofitting versus full system replacement can help you make the best choice for your needs.

Cost Comparison

Retrofit:

Retrofitting with Turbocor compressors is typically more budget-friendly, often costing 30-50% less than purchasing a new chiller. By upgrading to Turbocor compressors, you significantly lower operational costs through improved energy efficiency and reduced maintenance requirements. This can lead to substantial savings over the lifespan of the chiller, helping your facility recoup its investment faster.

Replacement:

Replacing a chiller involves a substantial upfront expense. Besides the cost of the new chiller, you must account for the expenses associated with removing the old unit, modifying infrastructure, and installing the new system. While new chillers come with improved technology, the high initial cost and potential for future maintenance and replacement parts can prolong the time it takes to see a return on investment.

System Disruption & Downtime

Retrofit:

A retrofit is typically less disruptive to your operations. It can be completed in a shorter timeframe, often without the need for extensive modifications to your existing mechanical room or infrastructure. This means minimal downtime and less disruption to your facility’s daily activities.

Replacement:

Replacing a chiller can be a complex and time-consuming process. It often requires significant modifications to accommodate the new unit, including potential structural changes, piping alterations, and possibly even a temporary shutdown of your cooling systems.

Environmental & Sustainability Considerations

Retrofit:

Retrofitting is inherently more sustainable as it reuses existing chiller components, thereby reducing waste and the environmental impact associated with manufacturing and transporting a new unit. Additionally, Turbocor compressors use environmentally friendly refrigerants like R134A, aligning with green building standards.

Replacement:

While modern chillers are designed to be more energy-efficient and environmentally friendly, the process of replacing an entire system generates significant waste. Furthermore, the new unit’s production and delivery add to your facility’s carbon footprint.

Performance & Efficiency Gains

Retrofit:

Turbocor compressor retrofits can drastically enhance the performance of your existing chiller. These compressors are oil-free and utilize magnetic bearings, leading to a significant reduction in friction, noise, and vibration. You can expect operational efficiency improvements of 25-50%, which translates to lower energy consumption and operating costs.

Replacement:

New chillers are designed with the latest technology, potentially offering higher baseline efficiencies and longer service lives. However, the efficiency gains need to be weighed against the cost and complexity of installation and the time required for the system to become fully operational.

Longevity & Future-Proofing

Retrofit:

A Turbocor retrofit can add up to 25 more years of life to your existing chiller. It provides a modern upgrade to your current system, keeping it competitive with newer units in terms of performance and efficiency without the immediate need for future replacements.

Replacement:

Investing in a new chiller can ensure your facility is equipped with the latest technology and efficiency standards. However, this also ties your capital to a single large investment, which may require future upgrades or replacements as technology evolves.

Choosing between retrofitting and replacing your chiller depends on several factors, including your budget, operational needs, and long-term goals. At Bullock, Logan & Associates, we specialize in both solutions and can help you evaluate your options to determine the best path forward for your facility.

Get Started with Turbocor Compressor & Chiller Retrofits Today

If you want to experience the benefits of an oil-free Turbocor compressor chiller retrofitting today, contact Bullock, Logan & Associates at any time. We’re ready to provide you with effective retrofitting that adds many years to your chillers while helping you save money. We also offer a range of other services for cooling and chilling systems such as rebuilding, repairs, and replacement parts as well as design assistance for new cooling and chilling systems. With our help, you can benefit from a chilling and cooling system that effectively contributes to your facility while remaining cost-efficient.

If Turbocor compressors/chiller retrofitting installation isn’t right for your facility, we may recommend a complete replacement chiller to restore your system to its original condition. Regardless of your needs, we’re ready to help you today.

Contact Us